|

||

|

NATURAL LatexNatural Latex, as its name implies, offers many benefits for use in sleep products. Consumers that have an organic lifestyle and have made numerous changes to remove most synthetic chemicals from their household tend to purchase 100% natural formulations. The elasticity, healthiness, and ability of Natural Latex to conform to your body, reducing pressure on your muscles and circulation is unsurpassed. The resulting benefits and luxurious comfort simply cant be matched by synthetic Latex. However, because it is a €œnatural€ product there are inconsistencies at the molecular level which cause Natural Latex products to wear at a faster rate than Synthetic Latex. |

|

MAKING Latex - Latex FORMULASBoth Talalay and Dunlop processes start with a formula mixture of liquid Latex. These formulas can be any of the following: 100% natural Latex rubber (harvested from rubber tree plants)100% synthetic Latex rubber (a man-made molecular copy of natural Latex rubber)Blended natural - synthetic Latex rubbers (specific blend ratios are proprietary) Note: there are small amounts of other materials required for processing liquid Latex into solid form which are necessary for all Latex production. (ingredients - amounts are proprietary) Latex International Talalay is produced using only 100% Natural or Blended formulations to meet optimum quality standards. |

|

|

|

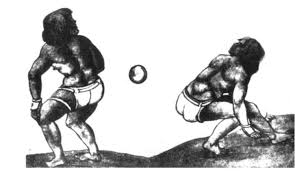

NATIVE TO THE AMAZON RAINFOREST NATURAL LATEX COMES FROM THE HEVEA BRASILIENIS TREE SEEDS, ORIGINALLY NATIVE TO THE AMAZON JUNGLES OF BRAZIL (THE FIRST BALL WAS INVENTED IN BRAZIL AROUND 3500 BC); TODAY, HEVEA BRASILIENIS TREES ARE GROWN IN TROPICAL CLIMATES AROUND THE WORLD. Latex is white and milky in appearance, has an elastic consistency, and is removed from the tree through a process called "rubber tapping" - similar to tapping trees for maple syrup. |

|

|

RUBBER TREE PLANTATION In the wild, the tree can reach a height of up to 100 feet (30m). The white or yellow Latex occurs in Latex vessels in the bark, mostly outside the phloem. These vessels spiral up the tree in a right-handed helix which forms an angle of about 30 degrees with the horizontal, and can grow as high as 45ft. In plantations, the trees are generally smaller for two reasons: 1) Trees grow slower when they are tapped for Latex, and 2) trees are generally cut after 30 years because Latex production declines as trees age, and they are no longer economically viable. The tree requires a tropical or subtropical climate with a minimum of about 1200mm/yr of rainfall, and without frost If frost does occur, the results can be disastrous for production. One frost can cause the rubber from an entire plantation to become brittle and break once it has been refined (needs reference). |

|

|

|

Process Each night a rubber tapper must remove a thin layer of bark along a downward half spiral on the tree trunk. If done carefully and with skill, this tapping panel will yield Latex for up to five years. Then the opposite side will be tapped, allowing this side to heal over. The spiral allows the Latex to run down to a collecting cup. The work is done at night or in the early morning before the day's temperature rises, so the Latex will drip longer before coagulating and sealing the cut. Depending on the final product, additional chemicals can be added to the Latex cup to preserve the Latex longer. Ammonia solution helps prevent natural coagulation and allows the Latex to remain in its liquid state. Plastic bags containing a coagulant have replaced cups in many plantations in Malaysia. This form of Latex is used as the raw material for Latex concentrate, which is used for dipped rubber products or for the manufacture of ribbed smoke sheet grades. Naturally coagulated Latex, sometimes referred to as cup lump, is collected for processing into block rubbers, which are referred to as technically specified rubbers (TSRs). The serum left after Latex coagulation is rich in quebrachitol, a cyclitol or cyclic polyol |

|

|

Harvesters make incisions across the Latex vessels, just deep enough to tap the vessels without harming the tree's growth, and the Latex is collected in small buckets. This process is known as rubber tapping. Latex production is highly variable from tree to tree and across clone types. |

|

|

|

Latex Foam Prehistoric uses

|

|

| Latex Foam

Rubber tapping Rubber tapping is the process by which the Latex is collected from a rubber tree. An incision is made in the tree's bark, which cuts through the Latex vessels, from which the product then flows. Timing of the incision must be planned within the planting cycle to optimise the Latex yield. Rubber tapping is an environmentally attractive land use. Jungle rubber is essentially old secondary forest, strongly resembling the primary forest. Its species' richness is about half that of the primary forest. Michon and de Foresta (1994) found that sample jungle rubber sites contained 92 tree species, 97 lianas, and 28 epiphytes compared to 171, 89, and 63, respectively, in the primary forest, and compared to 1, 1, and 2 in monoculture estates. Thiollay (1995) estimated that jungle rubber supports about 137 bird species, against 241 in the primary forest itself. Jungle rubber is expected to resemble primary forest in its hydrological functions. Monoculture rubber tree plantations have far less of an environmental impact than other crops, such as coffee or especially oil palm. In Information Technology the term 'Rubber tapping' is sometimes used as a lampoon for planned Production deployments, where the timing of the deployment is crucial. Such deployments are generally done late in the night when customer activity is minimum. |

|

|

GOTS Global Organic Textile StandardOnly textile products that contain a minimum of 70% organic fibres can become GOTS certified. All chemical inputs such as dyestuffs and auxiliaries used must meet certain environmental and toxicological criteria. The choice of accessories is limited in accordance with ecological aspects as well. A functional waste water treatment plant is mandatory for any wet-processing unit involved and all processors must comply with minimum social criteria. The key criteria of GOTS, its quality assurance system and the principles of the review and revision procedure are summarised in this section. |

|

|

| The "Global Organic LATEX Standard", GOLS in short, is the newly introduced standard for sustainable processing methods of LATEX products from organic raw materials. This mainly addresses the standards which need to be maintained with relevance to processing, manufacturing, packing, labeling, trading and distribution of LATEX products. In addition to the use of organic raw material, this standard also concentrates on aspects such as human health, safety and welfare, and environment in the manufacturing process of LATEX products. Product labeled as Made with Organic or Contains Organic should contain minimum 95%. or more of certified Organic LATEX (as per 2.1) and other certified Organic raw material (as per 2.2) in the final product, from its total weight. Balance 5% may contain non-organic products other than Natural or Synthetic LATEX. Any textiles materials used in the semi final or final products may be excluded from this calculation, however should be certified Organic as per GOTS standards or certified as per OE 100. | ||

|

|

||

|

|

||

1035 E. Camelback Rd., Phoenix AZ 800-733-181812557 Harbor Blvd., Garden Grove CA 800-824-3145907 Hollywood Way, Burbank CA 800-233-7382 Open Mon-Sat 10-5, Sun 12-4 SERVING ALL AREAS |

Control Union Certifications has pioneered the first global

standard for organic latex: the Global Organic Latex Standard (GOLS).

It is highly regarded, especially in the sleep products sector. GOLS

outlines requirements for latex products made from organic raw

materials, as well as for material from non-organic origins.

GOLS GLOBAL ORGANIC LATEX STANDARDS

Global Organic Latex Standards GOLS

The standard addresses criteria for natural rubber from certified

organic plantations (USDA NOP or EU) that is processed at

manufacturing units. To achieve GOLS certification, a

product must contain more than 95% of certified organic raw

material. The GOLS standard features permissible limits for harmful

substances, emission test requirements and polymer and filler

percentages. Rubber plantations as well as processing units up to

the final retailer are certified according to the standard. By using

transaction certificates at every sale of a product in the supply

chain, traceability from the plantation to the final retailer is

ensured.

|

||

| What is Natural Latex | What is the Talalay Process | Organic Latex |

|

|

|

| Adjustable Beds | Classic Talalay | Pressure-Mapping |

|

|

|

| 7" Latex Mattress | 9" High Profile | THE ULTIMATE |

|

|

|

907 Hollywood Way, Burbank CA

800-233-7382

1035 E. Camelback Rd.,

Phoenix AZ

800-733-1818

12557 Harbor Blvd., Garden Grove CA

800-824-3145

Open Mon-Sat 10-5, Sun 12-4 SERVING ALL AREAS

| 7" Latex Mattress |

| 9" High Profile |

| 11" THE ULTIMATE |

| 12" Springs & Latex |

| Certified Organic |

.jpg)